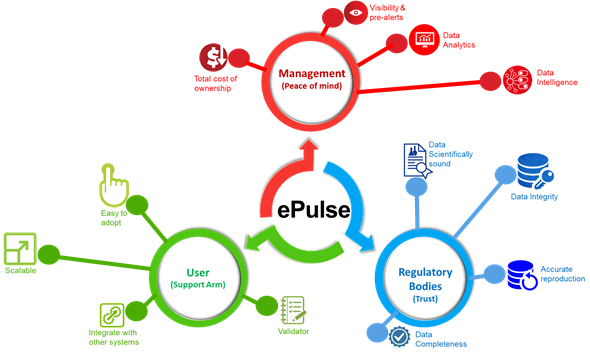

ePulse Solution Framework

A modular, digitalization production monitoring system that strengthens compliances

improves quality throughout by providing shop floor transparency and controlled

manufacturing activities.

ePulse addresses the existing operational challenges across the end to end pharma value

chain through technology led continuous

improvement and innovation.

Its different modules not only help to document every step in the production processes to

be compliant with today’s ever more stringent regulatory mandates, but also its IoT

technology component coupled with the use of advanced analytics is revolutionising how

pharma manufacturing function.

Monitor shopfloor Pulse with ePulse

eLog

Digitizing Log Journey

Presenting Electronic Logbook, complying with 21 CFR Chapter 11

requirements, a simple yet controlled platform for all Pharmaceutical

manufacturing to manage logbooks, digitally.

Complying with GMP guidelines, Electronic Logbook provides capability of

defining flexible workflow, SOPs on areas or equipment and building

validation control points and template builder to design templates.

Intelligence in system alerts in case there is a deviation from laid

procedures,

thus ensures compliance and data integrity.

Being a digital platform, it eliminates use of paper logs and with

available

data from digital logbooks, it further provides analytical capabilities

for

operational efficiency improvements which cannot be achieved using

manual

logbooks.

eOS

Equipment Agnostic IoT

Utilization is a key parameter for calculating OEE, eOS captures

single point of truth without directly integrating with the

equipment. eOS is a nimble IoT component which feeds pulse of

equipment on a real-time basis.

eOS, a non-invasive IoT component which can be attached to any

equipment or a machine to get a pulse of machine running or idle

status.

On

Status

Running

Status

Idle / Off

status

iMMS

Intelligent Manufacturing Monitoring System

iMMS is ERP/machine agnostic system providing capabilities of

real time data acquisition & production monitoring. It

integrates with available SCADA and PLC to acquire machine /

equipment data on a real-time basis.

Acquired data provides real-time / anytime process sheets and

also available as digital backup for future data archival. Data

acquisition further empowers alert & event logs which can be

proactively be used for required actions.

Data analytics provides insights on Batch Performance,

Equipment OEE, Breakdown patterns and manpower

utilization & efficiencies.

Utilization

Data Intelligence

Turning information into insights

ePulse not only converts value to data but also provides enablement

to businesses to improve safety & risk management.

It enables business to increase production of batches, reduction in

downtime and an improved OEE.

Data correlations provides insights on possible capacity release, route optimizations, quality / supervisor performance, manpower utilization and other multi-dimensional analysis.

Advantages

Designed with inputs from best of Pharma process owners & thus providing a Prebuild Module.

Agile Template Builder – Capabilities to build customized templates adopted at work environment

Powerful analytics for improved OEE and data insights

Integration compatibility with SAP / Other ERP Systems, LIMS and eLabs using web services or APIs

Simple UI/UX which makes the solution easy to understand & adopt.

Powerful workflow engine to ensure all tasks are executed as per defined workflow with digital signatures.

Multiple logging options other than login & passwords like Iris or face recognition .

Modular approach, thus provide easy scalability

Complies to GMP guidelines and 21CFR Chapter 11